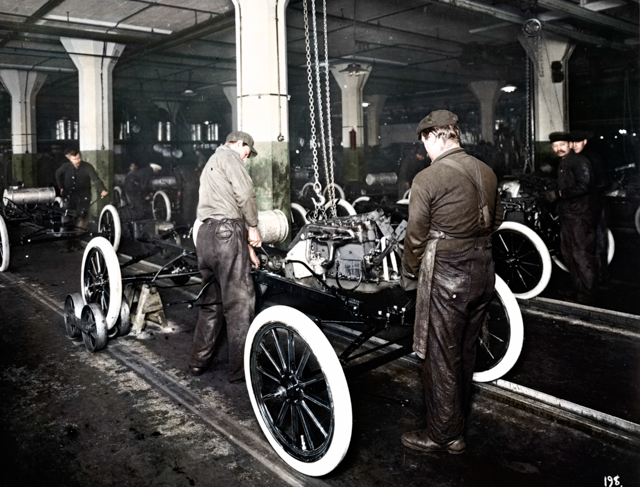

July marked the 100th anniversary of the moving assembly line, which was adapted by Henry Ford for Ford Motor Company. With this amazing milestone comes further innovation from Ford to the tune of major expansion in its advanced manufacturing skills and presenting brand new technologies that may rock the mass production world for generations.

With the former financial issues that plagued the auto industry seemingly a distant memory, increasing demand has made it essential for brands to come up with ways to more efficiently supply the market with vehicles. Ford plans to augment its already admirable international versatile manufacturing in order to create four different models simultaneously on the average at all of its plants by 2017. Also by 2017, Ford expects to be running 90% of its plants on three-shift, which not only would increase production by 30% but will also create massive amounts of jobs.

Ford executive vice president of global manufacturing, John Fleming, said, “Henry Ford’s core principles of quality parts, workflow, division of labor and efficiency still resonate today. Building on that tradition, we’re accelerating our efforts to standardize production, make factories more flexible and introduce advanced technologies to efficiently build the best vehicles possible at the best value for out customers no matter where they live.”

Ford is already living up to its goals in a big way by retaining 130,000 salaried and hourly jobs, globally. Ford is well on its way to producing 6 million automobiles in 2013. That translates into roughly 16 vehicles every single minute all over the world.